Research

Innovative Utilization of Waste Concrete Powder: Developing Eco-Friendly Cementless Binders

Waste concrete powder (WCP), a byproduct of aggregate recycling, poses a significant environmental challenge when disposed of in landfills. However, its chemical composition and potential for reactivation offer a promising opportunity for sustainable construction practices. WCP contains substantial amounts of SiO2 and CaO, along with hydrated phases such as anorthite, C-S-H, quartz, and calcite. When properly processed, it can be transformed into valuable cementitious materials. This study aims to reactivate WCP through thermo-mechanical activation, which offers multiple benefits, including reactivation of hydrated cementitious phases, removal of organic impurities, and reduction in particle size. This process transforms WCP into Thermo-Mechanically Activated Waste Concrete Powder (TMWCP), a viable alternative binder for concrete production. Given the cement industry’s significant contribution to global CO2 emissions, utilizing TMWCP as a cementless binder has the potential to reduce landfill waste, lower CO2 emissions from cement production, and conserve the natural resources typically used in traditional cement manufacturing. TMWCP can be applied across a range of concrete products, from conventional concrete production to advanced formulations such as Ultra-High-Performance Concrete (UHPC).

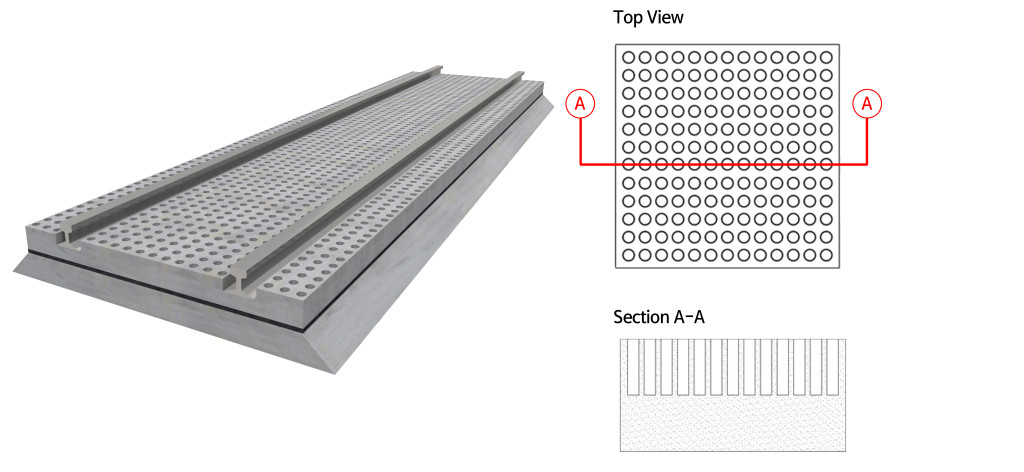

Railway slab track using Surface perforated mortar for Sound absorption

The noise produced by railways affects the lives of many people. This research aims to develop a structure that effectively absorbs sound. The porosity in the structure and the connection between the pores are the most important part in controlling sound absorption, but this comes at the cost of losing strength. Surface-perforated mortar (SPM) was developed by adopting the method of an acoustic panel that has macro-sized holes only on the mortar surface. The lower layer of SPM is a solid mat that could serve as a structural member of concrete slab track and the upper layer of SPM plays a role in railway noise absorption similar to non-structural sound-absorbing layers. The strength reduction ratio of SPM to non-perforated mortar can be less than that of porous concrete to non-porous concrete because of the solid mat in the lower layer. Having all the pores on the top of the structure increases the connection between the pores and increases the sound absorption of the system. In the study, the control of the absorption frequency range and peak enhancement will also be studied.

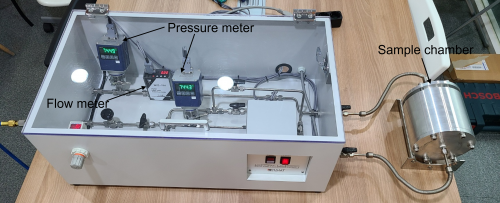

Minimize Gas Permeability of UHPC (Ultra High Performance Concrete)

Hyper tube express (HTX), a proposed new mode of transportation is a high-speed mode of transportation which consists of a sealed system of tubes with low pressure (0.001atm) where pods can travel free of air resistance with speed almost 1000km/hr. It can cover the distance from Seoul to Busan within 20 minutes as compared to 2 hr in present condition with KTX. A proposed tube material is UHPC due to its densely packed matrix and less sensitiveness to temperature and pressure variation compared to steel. We are currently studying the air tightness of UHPC, for its application in HTX.

Development of porous concrete for structural applications

This research aims to develop porous concrete (or pervious concrete) for structural applications to mitigate urban flooding and traffic noise. Because the low strength nature of porous concrete, the development of porous concrete for structural applications is challenging in order to meet both strength and porosity requirements. Industrial by products such as ground granulated blast furnace slag also adopted as binding materials to reduce the global warming by minimizing the usage of OPC. The ongoing studies are i) optimizing rheological properties of the binding materials by studying plastic viscosity, yield stress, and adhesion, ii) enhancing water permeability, iii) enhancing bonding strength with steel reinforcements, iv) enhancing durability and fatigue properties, etc.

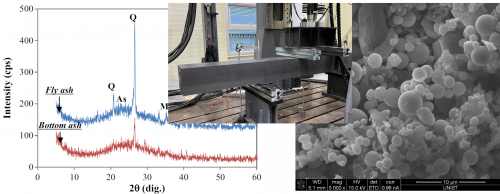

Sustainable solutions for the consumption of coal ash as construction materials

Due to its relatively inexpensive cost, many countries still use coal-fired power to generate electricity, which is responsible for more than 19% of the electricity in the world. However, this power generation method inevitably produces a substantial amount of coal ash such as fly ash and bottom ash, and the ashes that are not recycled are being put in landfills. To cope with this environmental problem, IMCT lab is working on various research: i) development of sustainable railway sleepers using recycled plastic and coal ash, ii) development of cementless high performance concrete using coal ash as aggregates, iii) development of the thermal insulation panel using bottom ash, etc.

FUNDED PROJECTS

KRISS (한국표준과학연구원) | A study on high‑performance cementitious materials for non‑destructive testing applications | Jan 2025-Dec 2025.

KAIA (국토교통과학기술진흥원) | Understanding the deterioration mechanism and developing prediction models for ultra high strength cementless concrete | Apr 2025-Dec 2028.

NRF (한국연구재단) | Development of cementless metaconcrete using industrial by-products and structural application technologies | Mar 2023-Feb 2033.

KRRI (한국철도기술연구원) | A study on the design of cementless concrete mix using recycled industrial by-products | Feb 2023-Nov 2023, Feb 2024-Nov 2024 & Feb 2025-Nov 2025.

KRRI (한국철도기술연구원) | Feasibility analysis of sound-absorbing materials applicable to railway infrastructure | Jun 2023-Nov 2023, Jul 2024-Oct 2024 & Apr 2025-Oct 2025.

NRF (한국연구재단) | A study on the development of structural porous concrete and the structural applications | Mar 2021-Dec 2023.

NRF (한국연구재단) | Development of carbon-neutral high-performance concrete for upcycling waste concrete powder and industrial byproducts from steel industry and thermal power plant | Sep 2021-Dec 2023.

NRF (한국연구재단) | Development of carbon-neutral high-performance cementless concrete and structural application technologies | Jun 2021-Feb 2024 & May 2024-Apr 2027 | co-PI.

NRF (한국연구재단) | Development of the Thermal Insulation Panel Using a Carbon-neutral Binder Made of Bottom Ash | Sep 2021-Sep 2022.

KRRI (한국철도기술연구원) | Development of UHPC and performance verification for Hypertube (HTX) application | Apr 2021-Oct 2021.

KAIA (국토교통과학기술진흥원) | Development of active wave absorbable structural materials for data infrastructure | Apr 2021-Dec 2022.

UNIST | Development of carbon-reducing permeable concrete based on artificial aggregate using industrial by-products | Mar 2021-Dec 2022 | co-PI.

NRF (한국연구재단) | A study on the reduction of railway noise through the development of structural vegetation concrete | Jun 2019-Feb 2021.

KAIA (국토교통과학기술진흥원) | Development of sustainable railway sleepers for upcycling of waste plastics | Apr 2019-Dec 2021.

KRRI (한국철도기술연구원) | A study on the analysis of the sound absorption characteristics and the durability of sound absorbable concrete for structural application | Feb 2019-Nov 2019 & Apr 2020-Nov 2020.

UNIST | Material characterization research on cement mortar after high power laser interaction | Jan 2019-Jan 2022.